Free Customization Solution

Our furniture come from the minds of BMS' respected designers with more than 30 years' experience in the industry.

Get Free PlansThis case study documents a real furniture product development project, from an unsuccessful prototype to a market-ready lounge chair, completed by the BMS Team in Foshan, China.

In high-end furniture manufacturing, successful products are rarely created in a single step. More often, they are the result of experience, cross-functional collaboration, and a deep understanding of structure, proportion, and craftsmanship.

This furniture product development case study shows how BMS, a high-end upholstered furniture manufacturer in Foshan, China, transformed an unsuccessful prototype into a refined lounge chair ready for mass production for an international furniture brand.

BMS has worked with an Australian furniture brand “T” for many years as a reliable private label furniture manufacturing partner.

One of the client’s core products, an upholstered sofa known internally as Model G, has shown a stable and strong sales performance in its market. Based on this success, the owner, Mr.S, proposed extending the collection by adapting the sofa into a lounge chair through a size reduction, expecting a faster development process using an existing structure.

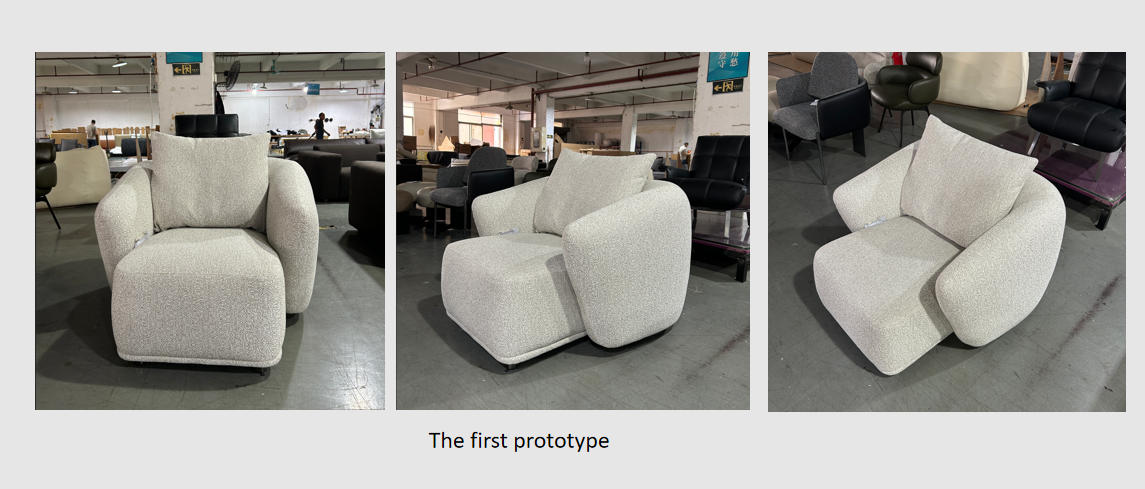

The first prototype was developed through a simple customization of the sofa’s original structure. While efficient in terms of time, the result did not meet the expectations of either the client or BMS.

Key issues identified included:

It was clear that this version was not suitable for market launch.

Once the issues were identified, Victor, the export sales manager, brought the prototype to the R&D team for immediate review. At BMS, furniture prototyping and sampling decisions are always made jointly by sales, design, and engineering teams.

During the discussion, Mr. Hu, Head of R&D, recalled a lounge chair he had seen at an international furniture exhibition. Although the reference photos were incomplete and taken from limited angles, they provided valuable direction in terms of posture, proportions, and visual balance.

Using:

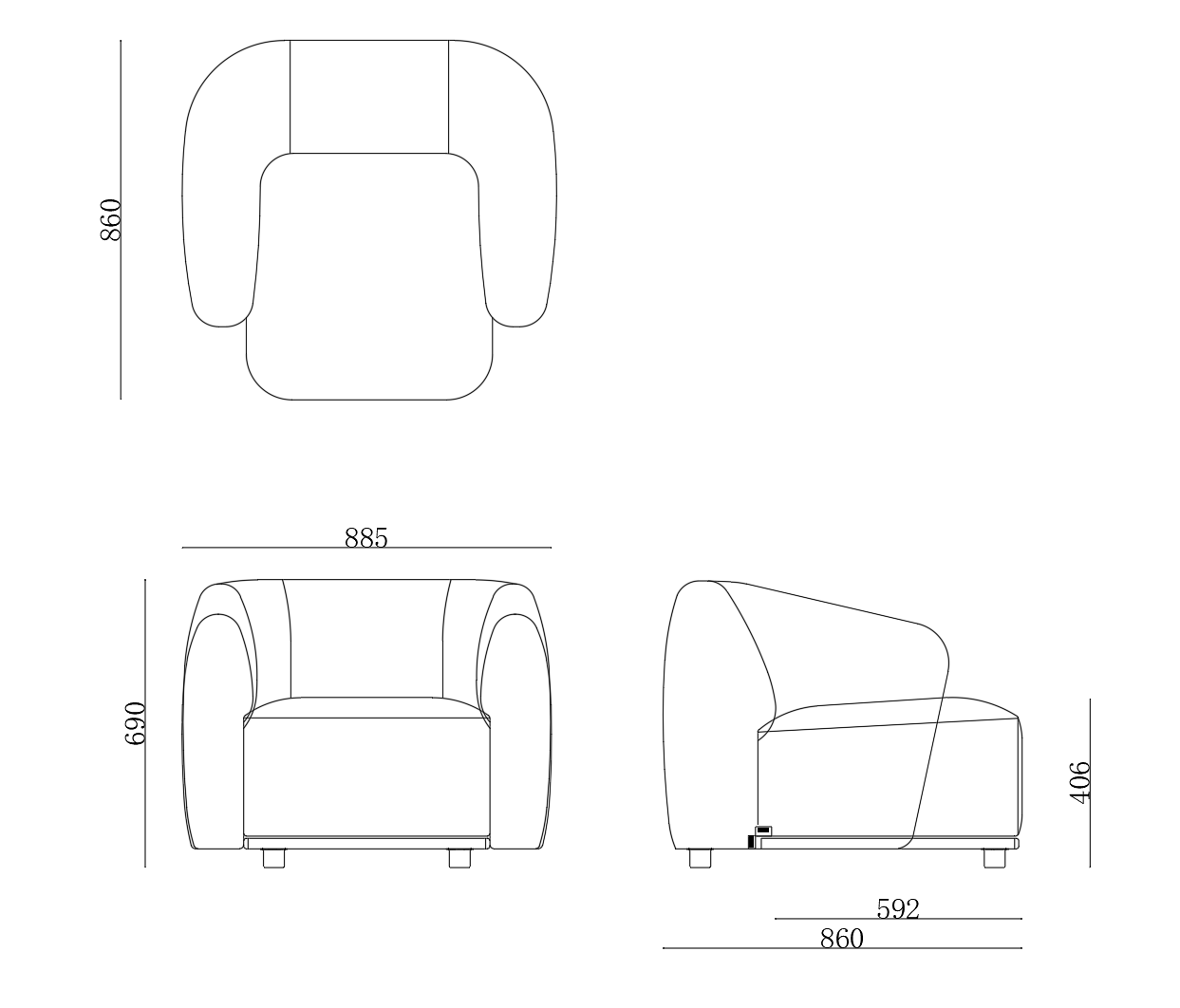

The design team developed a new CAD proposal. The objective was not to replicate an existing product, but to reinterpret the concept in a way that could be reliably manufactured at scale.

The CAD drawings were shared with the client for discussion. After several rounds of communication, both sides aligned on a clear improvement direction.

Due to significant changes in proportions and load-bearing requirements, BMS recommended developing a completely new internal structure and mold rather than modifying the original sofa framework.

This decision ensured:

This step marked the transition from simple customization to full lounge chair development.

The first sample met basic structural and comfort requirements. However, after internal evaluation by the export, design, and R&D teams, it was clear that the chair lacked visual softness and presence. The curves were not rounded enough, and the backrest did not fully express the intended organic form.

Clear optimization points were defined:

After two days of focused refinement, the second sample achieved a balanced combination of comfort, aesthetics, and manufacturability. This version was approved by the client as the final design for mass production.

During production planning, BMS identified increased complexity due to the chair’s organic curves and multi-directional upholstery work.

Discussions with experienced craftsmen confirmed that:

Although initially planned as a one-day process, each unit realistically required two days to complete while maintaining quality standards.

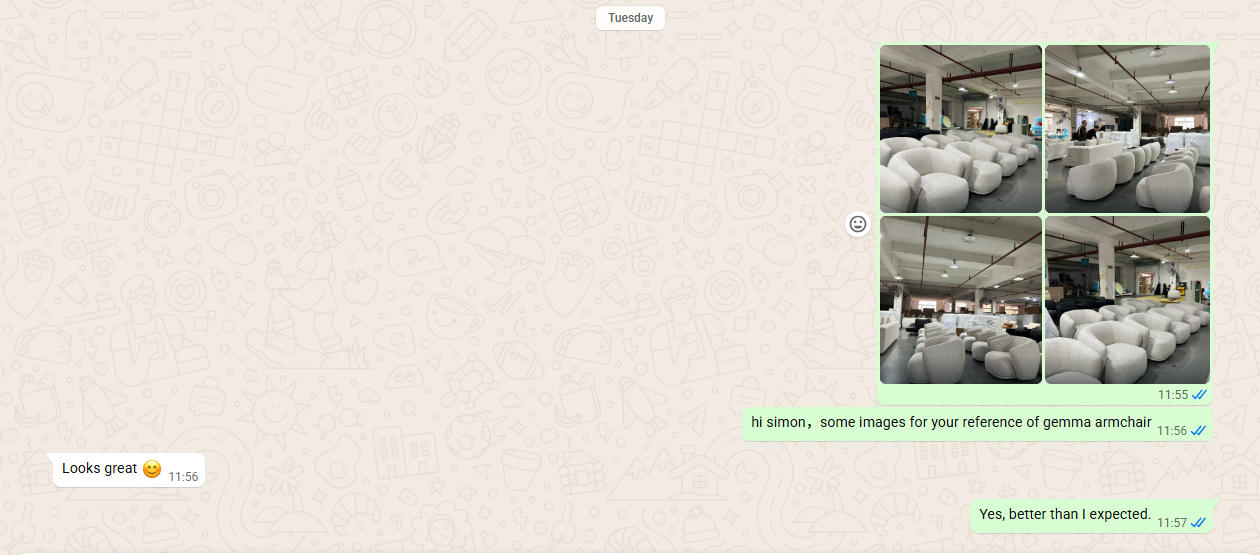

On January 20, the first batch of finished lounge chairs was completed.

Quality inspection confirmed:

Preview images were shared with the client, who expressed strong satisfaction and confirmed readiness for market launch.

This case study reflects how BMS approaches furniture product development:

We do not rely on surface-level customization.

We focus on structure, proportion, craftsmanship, and honest evaluation.

For furniture brands and retailers seeking a reliable furniture OEM partner in China, this project demonstrates how BMS manages real-world design challenges from concept to mass production.

Do you want to create your own collection? Contact us today for a free consultation.

BMS – High-End Upholstered Furniture Manufacturing Built for Long-Term Brands

Our furniture come from the minds of BMS' respected designers with more than 30 years' experience in the industry.

Get Free PlansBMS designers would love to add their imaginative but professional ideas to your design selection and customization.

Contact Now